|

| A miner crushes cobalt before it is tested for purity at the Kasulo mine in Kolwezi, Democratic Republic of Congo. A consortium of the world's top cobalt producers and users launched a pilot project to increase supply chain traceability through blockchain. Source: Sebastian Meyer/Corbis News via Getty News |

Leading U.S. electric vehicle manufacturer Tesla Inc. recently hopped on board a pilot program that uses blockchain to increase transparency along battery metal supply chains.

The technology, called Re|Source, will enable users to trace the provenance of cobalt, a metal used in a variety of EV batteries, "from upstream cobalt production facilities in the Democratic Republic of the Congo to downstream electric vehicle productions sites," according to Glencore PLC. The Swiss mining company is one of the world's largest cobalt producers and a founding Re|Source member.

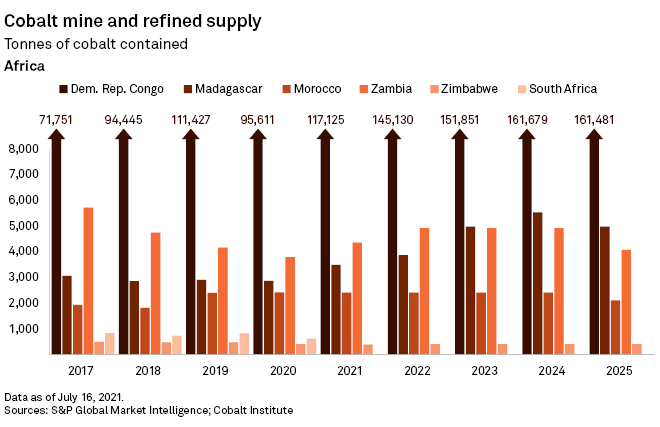

Fellow mining companies China Molybdenum Co. Ltd. and Eurasian Resources Group SARL are also founders of the group. The team of companies intends to pilot the platform in DRC, where the majority of cobalt is mined, and in Europe, Asia and the U.S., Glencore said. In 2020, DRC produced 95,911 tonnes of cobalt, accounting for 68.9% of the world's mine supply, according to S&P Global Market Intelligence data.

"Tesla selected to collaborate with Re|Source because it is industry-led, is designed to be readily accessible and inclusive to all parties across the supply chain and is scalable, which means it can include other critical battery materials in the future," Tesla stated in an August impact report.

While there have been several proposals to use blockchain databases to track metals along the supply chain, Tesla's decision to sign onto Re|Source could make a difference in helping the blockchain technology transition to a commercial scale, according to industry experts.

Re|Source will be piloted in 2021 and the group plans to launch the full platform in 2022, Tesla said. The company also started collaborating with mining giant BHP Group to track nickel from its Nickel West mine in Australia to a factory in Shanghai where EVs are manufactured.

In the meantime, global cobalt mine supply is expected to accelerate in response to rising demand, with S&P Global Market Intelligence analysts forecasting total cobalt output reaching 221,970 tonnes by 2025, about 60.0% more than 2020 production.

Pressure from consumers, companies

Making an EV battery requires a number of metals, such as cobalt, nickel and lithium, and the route these commodities take between extraction and sale can be shrouded in secrecy. As countries around the world mobilize to electrify transportation and energy sectors, metals companies and customers have intensified their scrutiny of human rights and environmental conditions at mining sites and processing facilities.

Calls for greater traceability along critical mineral supply chains have become increasingly common, Benchmark Mineral Intelligence analyst George Miller said.

"I think the real driver behind that is consumer attitudes toward supply chains," Miller explained. "They want to know that the lithium and minerals going into their electric vehicles are as green as they possibly can be and in alignment with the end-product, which is the electric vehicle itself."

Traceability platforms like Re|Source intend to fill in these gaps by applying a unique code to supplies and tracking them across the supply chain.

"Projects like Re|Source are about managing risks while giving that certainty and assurance downstream, and ultimately to customers," Adam McCarthy, president of the Cobalt Institute, said in an interview. The institute serves as a strategic advisor for the project. "That is what we seek to do so that you can ultimately use cobalt knowing that there are challenges, there are risks, but the industry is doing the things they need to do to address them. That is what this project can do."

McCarthy also called Re|Source "unique" compared to similar proposals because it aims to span the entire supply chain, and it has the backing of the industry's top producers and customers.

But that doesn't mean achieving widespread traceability will be easy.

"Supply chain provenance tracking gets pretty tricky when it comes to things like metals [such as] lithium," said Abigail Wulf, director of critical minerals strategy at Securing America's Future Energy, or SAFE. "If you are smelting down or refining a metal to about 99.99% purity, it loses its unique signature."

SAFE advocates for greater U.S. mineral independence in part by increasing domestic sourcing of critical minerals and partnering with allied nations that uphold stronger worker and environmental standards.

Implementing safeguards along global value chains can be challenging, yet Wulf considers the rise in blockchain proposals promising. SAFE is also advocating for the U.S. Geological Survey to develop a more robust framework to track mineral provenance to help increase supply chain transparency.

"We want to create transparent supply chains using technology such as blockchain to make sure that people are adhering to these high standards, which we think will ultimately help benefit American and North American-allied workers and bring those supply chains back to our shores," Wulf said.

Despite the promise seen in technologies, there isn't necessarily a silver bullet, industry experts said.

"Traceability is important, but in a global value chain, we need to do more," McCarthy said. "What we have seen [work] is engaging with local communities, making sure there are certifiable standards and coupling that with using new and emerging technology for traceability."