S&P Global Offerings

Featured Topics

Featured Products

Events

S&P Global Offerings

Featured Topics

Featured Products

Events

S&P Global Offerings

Featured Topics

Featured Products

Events

Banking & Capital Markets

Economy & Finance

Energy Transition & Sustainability

Technology & Innovation

Podcasts & Newsletters

Banking & Capital Markets

Economy & Finance

Energy Transition & Sustainability

Technology & Innovation

Podcasts & Newsletters

S&P Global Offerings

Featured Topics

Featured Products

Events

7 Jul, 2021

By Corey Paul

A startup backed by Bill Gates' clean-energy fund plans to launch a pilot project by the end of 2022 that will be capable of cutting CO2 emissions from hydrogen production while still using natural gas.

The company, California-based C-Zero Inc., is working to commercialize a technology that splits methane into hydrogen and carbon by moving it through a mixture of molten salts.

One advantage of this process, known as pyrolysis, is that the carbon extracted from the methane is in solid form, which makes it possible to avoid the challenges associated with injecting the gas CO2 underground to sequester it. Another is that pyrolysis can slash emissions while accommodating the use of existing natural gas infrastructure. If biological sources of natural gas are used, such as methane from agricultural facilities, then pyrolysis can also be emissions negative, removing methane that would otherwise escape into the atmosphere.

"If we are serious about climate change and we are serious about needing to draw down CO2 emissions as quickly as possible, we need to use our existing infrastructure," said Fadl Saadi, C-Zero's director of business development and operations, during a July 7 event by the Atlantic Council's Global Energy Center. "We have a massive infrastructure of natural gas capacity, both in the United States and globally. When you look at it from a global perspective, we simply don't have the time to rebuild all of our energy infrastructure."

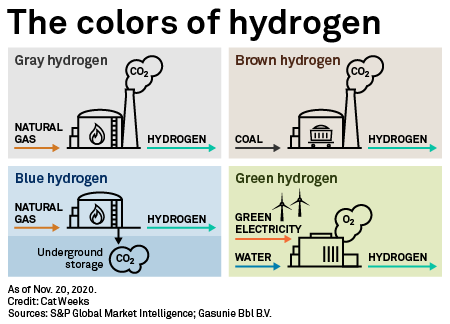

This product of pyrolysis is sometimes known as "turquoise hydrogen," because it combines the benefits of other forms of hydrogen. Green hydrogen comes from electrolysis of water powered by renewable electricity, and blue hydrogen comes from a process that pairs carbon capture with steam methane reformation of natural gas.

C-Zero touts pyrolysis as a way to decarbonize a wide swath of the energy system, including power generation, heavy industrial heating and the production of commodity hydrogen for fuel cells, synthesizing ammonia or refining. The process uses 7.5 times less energy to produce hydrogen than electrolysis, according to the company.

The pilot project due at the end of 2022 will be able to produce about 250 kg/d of hydrogen, C-Zero said. Next, the company will develop its first commercial unit, which would be capable of producing about 6,000 kg/d, the company said.

"All with an eye, however, toward making sure that what we are working on today can be scaled up all the way to world-scale plants," Saadi said. He said the plants would be capable of producing 270,000 kg/d, or 100,000 tonnes per year, which is the traditional size of steam methane reformation facilities.

Saadi said C-Zero is interested in locating its facilities close to where the hydrogen would be consumed, such as the site of a combined-cycle natural gas power plant, although pyrolysis could be deployed at various points of the natural gas supply chain.

The Gates-led Breakthrough Energy Ventures LLC has described the technology that C-Zero is working on as "critical to decarbonizing the agriculture, manufacturing, and transportation sectors." Breakthrough Energy and Eni SpA announced in February that they co-led a funding round to raise $11.5 million for C-Zero. Some of the other backers included the U.S. Department of Energy, Southern California Gas Co. and Mitsubishi Heavy Industries Ltd.

One of the primary challenges with pyrolysis is lowering the cost of the technology at a large scale. Green hydrogen produced with renewable resources costs between about $3/kg and $6.55/kg, according to the European Commission's July 2020 hydrogen strategy. Fossil-based hydrogen costs about $1.80/kg, and the commission estimated the cost of blue hydrogen at about $2.40/kg.

Saadi said C-Zero plans to make the product of its technology "quite competitive" with blue and green hydrogen, but he did not offer a production cost estimate of the commercial facilities that the company has planned.

"We think this is only a good idea if two macro factors are true," Saadi said. "The first is concern over CO2. The biggest tradeoff with this technology is that you are leaving 40% of the energy behind in the form of solid carbon, and you wouldn't do that if you didn't care about your CO2 emissions. The second is access to low-cost natural gas."