Featured Topics

Featured Products

Events

S&P Global Offerings

Featured Topics

Featured Products

Events

S&P Global Offerings

Featured Topics

Featured Products

Events

S&P Global Offerings

Featured Topics

Featured Products

Events

Financial and Market intelligence

Fundamental & Alternative Datasets

Government & Defense

Professional Services

Banking & Capital Markets

Economy & Finance

Energy Transition & Sustainability

Technology & Innovation

Podcasts & Newsletters

Financial and Market intelligence

Fundamental & Alternative Datasets

Government & Defense

Professional Services

Banking & Capital Markets

Economy & Finance

Energy Transition & Sustainability

Technology & Innovation

Podcasts & Newsletters

31 May, 2022

By Garrett Hering and Darren Sweeney

| Tesla batteries on fire in July 2021 at Neoen's Victorian Big Battery project in Australia. The root cause was likely a coolant leak, an investigation found. |

Vistra Corp.'s Moss Landing Energy Storage Facility on California's Monterey Bay, celebrated as the world's largest lithium-ion battery station, is scheduled to resume commercial operations in June after separate outages in February and, before that, in September 2021 sidelined one of the Golden State's most essential energy transition assets.

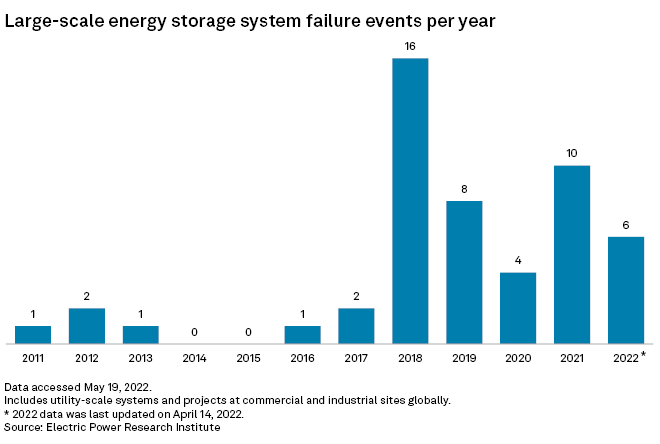

The breakdowns are among more than 50 known failures at medium- to large-scale battery storage projects in the U.S., Europe, Asia and Australia. Daily outage reports from the California ISO, which has more battery storage on its network than any other grid operator, point to additional frequent "plant troubles" curtailing capacity that the state is counting on to keep the lights on during critical periods of peak demand.

Ranging from limited operational hiccups to catastrophic explosions, such incidents are likely to continue to accompany the proliferation of battery peakers, technology and safety experts said. This highlights the significant risks that utilities and their suppliers face as they invest billions of dollars to decarbonize power grids with electrochemical energy storage.

"I think that for the next five, 10 years, we'll still be struggling with similar issues," said Michael Mo, CEO of KULR Technology Group Inc.

The San Diego-based battery safety specialist, whose team has worked with NASA on lithium-ion batteries operating in space and on Mars, believes technology developers need to do more to guard against failure.

"I don't want to offend people," Mo said, "but it's more like the ostrich approach: Stick your head in the sand and pretend it doesn't happen."

Despite the challenges at Moss Landing and other storage projects, Vistra CEO Curt Morgan defended lithium-ion batteries as safe, sound and necessary to maintain reliability while integrating massive new volumes of variable wind and solar power into the grid.

"They are no different than any technology that I've been around that's new," Morgan said in an interview. "There's always growing pains in new technology, and we certainly learned something from our largest-scale-in-the-world battery installation out at Moss Landing."

'Imminently fixable'

"Interestingly enough, it wasn't the batteries. It was the water-based heat suppression system, the safety system that is supposed to cool the batteries down if they overheat, that actually malfunctioned and created a situation where there was overheating of the batteries," Morgan said.

"That is imminently fixable because that is about controlling water supply, and we do that all the time," Morgan added. "I'm not happy that we had to go through it, but that is the way it is sometimes. You learn from your mistakes and from others' mistakes. You fix it, and then you move on."

Morgan expects about 200 MW to come back online in early June, followed by another 150 MW in late June or early July and the remaining 50 MW operational in August. That would come just as California's grid enters its most vulnerable period of high demand and exposure to wildfires, heat waves and drought.

After negotiations that the Vistra CEO described as "not easy," PG&E Corp. operating arm Pacific Gas and Electric Co. signed on for an additional 350 MW/1,400 MWh from Moss Landing, starting in August 2023. The California Public Utilities Commission in April approved the 15-year agreement, overriding opposition from its ratepayer advocacy office.

Vistra plans to build up to 1,500 MW/6,000 MWh of energy storage at the site, shared with its natural gas-fired Moss Landing CC plant.

"I'm definitely comfortable that batteries can work and will work, and they will be a part of the solution," Morgan said.

Vistra's experience at Moss Landing is not an isolated one.

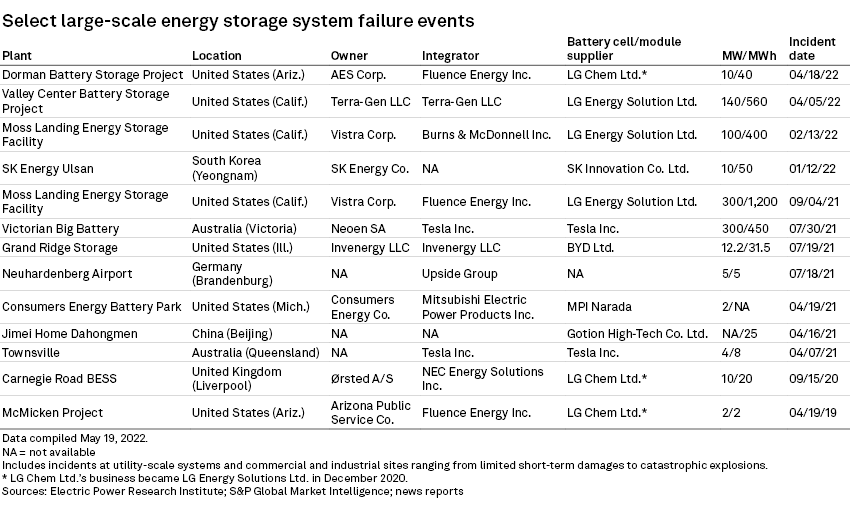

Two Tesla Inc. Megapacks consumed in a July 2021 fire at Neoen SA's Victorian Big Battery Storage Power Plant in Australia also "most likely" started with a cooling system problem, according to an independent investigation released in January. During plant commissioning, a coolant leak in one Megapack triggered arcing in power electronics that ultimately led to thermal runaway and a blaze that spread to an adjacent unit.

The two destroyed Megapacks were replaced and the 300-MW/450-MWh system was completed in December 2021.

'Law of numbers'

As Vistra readies Moss Landing for relaunch, AES Corp. is just beginning to assess the damage to its 10-MW/40-MWh Dorman Battery Storage Project in Chandler, Ariz., which caught fire in April due to unknown causes. Fluence Energy Inc., a storage integrator launched in 2018 by AES and Siemens AG, supplied the Dorman system.

It was the third failure among roughly 150 Fluence-built energy storage projects. The company also provided the first 300-MW phase of Vistra's Moss Landing project, as well as Arizona Public Service Co.'s 2-MW McMicken battery storage facility, which exploded in Surprise, Ariz., in 2019, injuring eight firefighters and destroying the project.

An investigation attributed the Surprise incident to internal failure in an LG Chem Ltd. lithium-ion battery cell that initiated thermal runaway, which cascaded after a safety system failed to halt progression across flammable battery electrolytes. This led to hazardous gases concentrating inside a container with insufficient ventilation. An emergency response plan, later found to be lacking, contributed to the explosion.

In Chandler, the emergency plan was much improved, resulting in no injuries. AES and Fluence executives cautioned against speculation over what caused the fire.

"There will be some things that we immediately take away and some things that we share with others to think about how you do this," said John Zahurancik, president of Fluence's business in the Americas.

Significantly, none of the three troubled Fluence projects used the company's sixth-generation technology. Introduced in 2020, the platform relies on a smaller number of batteries inside cube-like assemblies only accessible from the outside, rather than a larger number of batteries inside standard shipping containers or buildings, to enhance safety.

"What we did with Gen 6 is we created a smaller containerized unit. And so when you do have any kind of event, you have it contained basically to that one box," Zahurancik said. "The other thing is, because those units are isolated that way, it also means you probably can restore that faster."

But there will always be some risk, Zahurancik added. "It's just law of numbers, right?"

Battery safety technology expert Michael Mo agreed.

"No system, no technology is perfect," Mo said. Of the billions of lithium-ion battery cells now produced each year, thousands could have defects, according to Mo. "Just statistically speaking, these cells are going to short, inherently."

|

A July 2021 battery fire in Brandenburg, Germany. |

Beware of 'bigger grenade'

All players across the transportation and power sectors are exposed to the risks of lithium-ion battery failure, from manufacturers and product owners to companies that package, ship, store and recycle batteries.

In 2021, a Michigan-based subsidiary of LG Energy Solution Ltd. recalled roughly 10,000 residential batteries sold throughout the U.S. after receiving five reports of wall-mounted batteries smoking and catching fire, leading to property damage and one injury, according to an August 2021 notice from the U.S. Consumer Product Safety Commission.

The systems were sold through various home solar providers including Sunrun Inc., the country's largest residential solar installer.

In Australia, regulators on May 20 warned owners of LG home batteries to "urgently check" if their systems were subject to a February 2021 recall affecting about 7,200 units because more than 6,400 still had not been replaced.

"These batteries have already caused injury and fire damage to properties and could lead to serious injuries or death," Delia Rickard, deputy chair of the Australian Competition & Consumer Commission, said in a statement.

The battery supplier is "continuing its efforts on replacing residential battery system units that are subject to recalls," a spokesperson for LG Energy Solution said in an email, adding that the company is making "prudent" investments to "revamp quality and raise product competitiveness."

The residential recalls were followed in October 2021 by General Motors Co.'s announcement that LG Electronics Inc. would reimburse the automaker for $1.9 billion in charges associated with its recall of Chevrolet Bolt electric vehicles, which encompassed all 2017-2022 model year Bolts.

LG Energy Solution is partnering with GM to invest billions into battery cell plants in Michigan, Ohio and Tennessee.

LG Corp. is the largest public shareholder of LG Electronics and LG Chem, and LG Chem is the largest public shareholder of LG Energy Solution.

As the technology advances and developers make more powerful batteries, larger safety issues loom, according to Mo.

"Then you just [have] a bigger grenade in your hand," Mo said.

Tom Jensen, CEO of European battery upstart Freyr Battery, intends to navigate around the early thermal runaway problems with lithium-ion batteries in part by relying on a "dramatically simplified" production process to greatly reduce the possibility of contamination-caused defects that often trigger thermal runaway.

Freyr, which has begun site preparation for its first manufacturing hub in Norway, uses a semi-solid cell technology designed by Massachusetts-based licensing partner 24M Technologies Inc. and is exploring U.S. production through a joint venture with Koch Industries Inc.

When exposed to a crash or other external damage, conventional batteries can behave like brittle "potato crisps" and can break, while the 24M technology's pliable clay-like structure reacts more like "Juicy Fruit" and simply bends, according to Jensen.

"We believe that the safety features of this technology [are] an increasingly important competitive edge," Jensen said. "Safety is paramount to what we're doing."

S&P Global Commodity Insights produces content for distribution on S&P Capital IQ Pro.